Pepperl+Fuchs has played a decisive role in the history of electrical explosion protection: from the beginnings of intrinsic safety to today’s industry-changing technologies such as Ethernet-APL, our resourceful engineers have always been involved in shaping the industry over the past decades. Therefore, you can be sure that with Pepperl+Fuchs you have exactly the right partner at your side if you are looking for a functionally mature and absolutely safe solution for measuring, controlling, switching, and distributing in hazardous areas.

Our experts help you choose the best technologies from our portfolio to meet your requirements and comply with relevant standards and regulations. We develop the specifications together, and our global Solution Engineering Centers specialized in customized solutions implement them according to your requirements. You receive a fully certified, turnkey solution that ensures the highest level of safety in your plant’s explosionhazardous areas.

Trust the experts.

Throughout the entire process of an engineered solution, we always work in close collaboration with you. This is why Pepperl+Fuchs has set up Solution Engineering Centers around the world. The SECs are dedicated to engineered solutions for process automation that meet your individual requirements. No matter where you are, our experts take care of everything for you: from consulting to drafting the proposal and initial solution, to engineering and designing, to manufacturing and assembly, to the final solution, including certification.

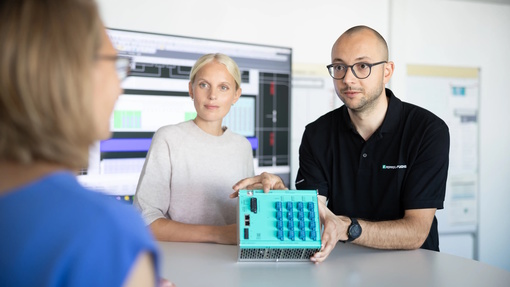

In close partnership with you, our experienced experts in our Solution Engineering Centers (SEC) plan, develop and design engineered solutions for explosion-hazardous areas, including certification. Watch the video to see the entire process of such an engineered solution—from the initial inquiry to shipment.

As soon as we receive an inquiry for an engineered solution, a detailed analysis of the specific application and individual requirements is our first step—in order to ensure a deep understanding of your needs. This includes comprehensive consultation and close collaboration with you. Based on that, our experts develop a first solution proposal as well as a timeline and a budget plan.

As an expert in explosion protection, we can draw on a broad range of products and technologies for hazardous areas that are the basis for our engineered solutions. Depending on the application and your individual requirements, we choose the best combination of products to solve your task in the best possible way.

In the Solution Engineering Centers around the world, our experienced engineers take care of the detailled engineering of your solution. They design a model of your solution and create manufacturing documents and customer approval drawings. Once you have given your approval, the required material is procured, and the solution is ready for manufacturing.

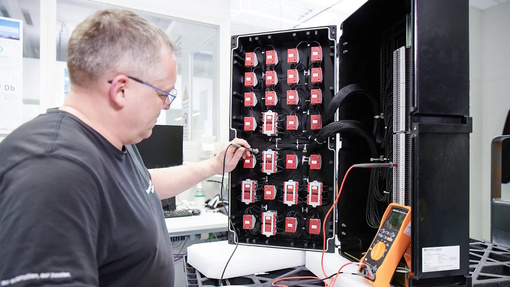

The explosion protection solutions are fully assembled in our SECs own production facilities around the world. Assembly parts are manufactured, and raw materials as well as purchased parts are ordered. As soon as everything is available, our experts assemble the finished solution step by step. Whether in a dedicated production line for configured solutions or in the manufacturing area for engineered solutions, we find the fastest way to implement them.

Every SEC has an in-house quality assurance. Here, the finished solution is put through its paces again before it is ready for your acceptance. Individual test procedures and the use of specific testing software according to your demands are possible, if required.

As soon as a finished solution has passed our quality assurance, it is ready for the factory acceptance test (FAT). Our SECs offer on-site FAT areas where your personal contact person goes through the solution together with you.

Thanks to decades of experience in electrical explosion protection, we are familiar with all relevant norms and standards (e.g., ATEX, IECEx, UL) as well as other country- or industry-specific certifications. Our standards experts are involved in the process of an engineered solution from start to finish so that they can be delivered with the corresponding declaration of conformity and the required certification.

Whether packed in a wooden crate or wrapped in plastic, we prepare your customized solution for shipment exactly as you need it. From our six SECs around the world, the finished solutions make their way to you.

Download our overview brochure for customized solutions as a free PDF now.